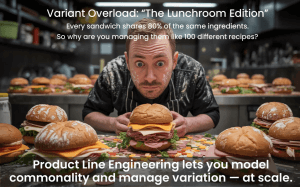

Imagine you walk into your favorite sandwich shop. You order a turkey club — nothing unusual. But instead of reaching into the same pantry they used for the last 100 turkey clubs, the chef starts reinventing the recipe from scratch. New bread supplier, new lettuce, new turkey…all sourced, tested, and prepared just for you.

Ridiculous? Wasteful? Inefficient?

That’s exactly what happens in many organizations that manage product families without Product Line Engineering (PLE).

The Sandwich Shop From Hell — and What It Teaches Us About Product Lines

Running a product portfolio without PLE is like running a kitchen where:

1. No Standardized Ingredients

Instead of pulling from a shared pantry of common components, validated modules, and proven designs, teams start from scratch every time they build a variant.

In engineering terms: there’s no master library, no controlled asset reuse — just reinvention.

2. Reinventing the Wheel — Again and Again

Every variation is treated as a separate development project. That means:

- Duplicate design work

- Repeated testing cycles

- Inconsistent quality across variants

The result? Slower releases, higher costs, and more defects sneaking into production.

3. A Simple Change Becomes a Big Deal

A customer says, “Hold the pickles.”

In a smart kitchen, you’d just take them off.

In a no-PLE environment? The entire recipe is rebuilt, retested, and re-released — even though 80% of the “ingredients” are identical.

4. The Variant Kitchen Is a War Zone

Without centralized control, engineering environments become cluttered with:

- Duplicated artifacts

- Inconsistent toolchains

- Conflicting design decisions

It’s almost impossible to know what’s shared, what’s unique, or what will break when a change is made.

5. Innovation Gets Smothered

When your best engineers spend all their time chasing down minor variations, there’s no space left for big-picture innovation, R&D, or strategic growth.

You’re always in reaction mode instead of building the future.

The PLE Way — Scaling Without Scaling Chaos

Product Line Engineering turns the sandwich shop chaos into a Michelin-star operation.

With PLE — and tools like Pure::Variants from PTC — organizations can:

- Model variation at scale

- Standardize and reuse proven assets

- Maintain a clear separation between shared and unique features

- Speed delivery without sacrificing quality

The result? Less duplication, faster releases, and more time for innovation.

Real-World Impact

At 321Gang, we help engineering organizations transition from manual, siloed variant management to a streamlined PLE approach with Pure Variants.

We’ve seen:

- 30–50% reduction in development cycle time

- Dramatically lower defect rates in variant-specific releases

- Teams freed up to focus on high-value innovation instead of repetitive rework

Ready to Stop Reinventing the Sandwich?

Whether you’re just starting to feel the pain of manual variant management or already drowning in duplicated artifacts, we can help you:

- Identify reuse opportunities

- Model your product line for scale

- Implement the right PLE tooling and practices

Your product portfolio — and your engineers — will thank you.

If you are interested in learning more, contact 321Gang.

321Gang | 14362 North FLW | Suite 1000 | Scottsdale, AZ 85260 | 877.820.0888 info@321gang.com