Automotive Systems Engineering and Model-Based Variant Management

So, in the world of automotive systems engineering, guess what’s driving all the cool new customer features? It’s those ever-changing trends in electrification, automation, and connectivity. We’re talking about everything from fancy sensor tech for understanding what’s happening around your car to digital maps and all sorts of services, whether they’re behind the scenes or right on your mobile device. But here’s the kicker: what’s really making all of this happen is the systems and software running in today’s cars. Believe it or not, your average new-model car packs a whopping 100 million lines of code! As these systems become more interconnected, it’s getting trickier to figure out where one ends and the other begins.

and connectivity. We’re talking about everything from fancy sensor tech for understanding what’s happening around your car to digital maps and all sorts of services, whether they’re behind the scenes or right on your mobile device. But here’s the kicker: what’s really making all of this happen is the systems and software running in today’s cars. Believe it or not, your average new-model car packs a whopping 100 million lines of code! As these systems become more interconnected, it’s getting trickier to figure out where one ends and the other begins.

Now, all these technological advances are cool, but they’re also bringing some challenges to the table, especially when it comes to the old-school development processes. Shorter development cycles are the new norm, and vehicle development has gone global, with teams scattered all over the planet. This global teamwork means we need to shake up those traditional methods and tools. And hey, dealing with different target markets and their rules and standards? We’ve got to find a unified way to handle it all. That means keeping a close eye on every step of development, making sure everything’s documented and accessible online, and even prepping for those software updates that happen after your car’s rolled off the factory floor. It’s like a complex juggling act that involves organizational processes, methodologies, tools, and more.

So, say hello to variant and configuration management, two big players in the world of successful product development. With all the changes happening in tech and how we do things, having a structured approach to managing different versions of a system is a must. This approach needs to cover every stage of systems engineering and cater to the various roles involved in a product’s life. The goal? Making it easier to reuse systems and functions and quickly check out new technical solutions.

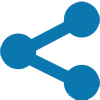

Now, let’s dive into Automotive Systems Development. To meet those high standards for automotive products in terms of quality, durability, and safety, we’ve set up some rigorous development processes and procedures. One of the favorite models in this realm is the V-Model [fig 1], which guides systems engineering in car manufacturing. It’s a step-by-step process, starting with top-down analysis and design and ending with integration and testing. The V-Model focuses on development stuff, activities, and roles, all in an iterative dance that keeps everything in check.

Systems engineering plays a significant role here. It’s like the conductor of an orchestra, bringing together various processes, methods, and tools to create complex systems. An important component is model-based development, which puts the emphasis on simplifying systems by breaking them down into manageable parts. Different models give different views of the system, making it easier to understand and work with.

But there’s a twist in automotive development. While the car manufacturer handles the top-level design and integration, lower levels like component design are often outsourced to different suppliers. This introduces some challenges, especially when it comes to highly interconnected systems. Strong communication and well-defined interfaces are the name of the game.

Now, let’s move to a Model-Based Variant Management Approach. We’ve got a feature-based strategy for managing variants of systems during development. These variants can come from customer needs, regulations, or pop up during the development process itself. Automotive systems are incredibly complex, so engineers use a modular and hybrid characteristics model to break them down into manageable chunks, from the early concept phase all the way to production.

This approach allows engineers to describe variants based on these characteristics, whether we’re building from the bottom up or the top down. It’s a versatile system that’s all about flexibility.

There are some exciting modern variant management approaches that tackle the challenges of modeling and describing variants in the early stages of systems development in the automotive industry. It’s all about using feature models to provide consistent and model-based variant descriptions from various perspectives and roles.

IBM ELM Global Configuration Management, Pure Variants, and 321Gang offer a powerful combination to implement a modern variant management solution in the automotive industry:

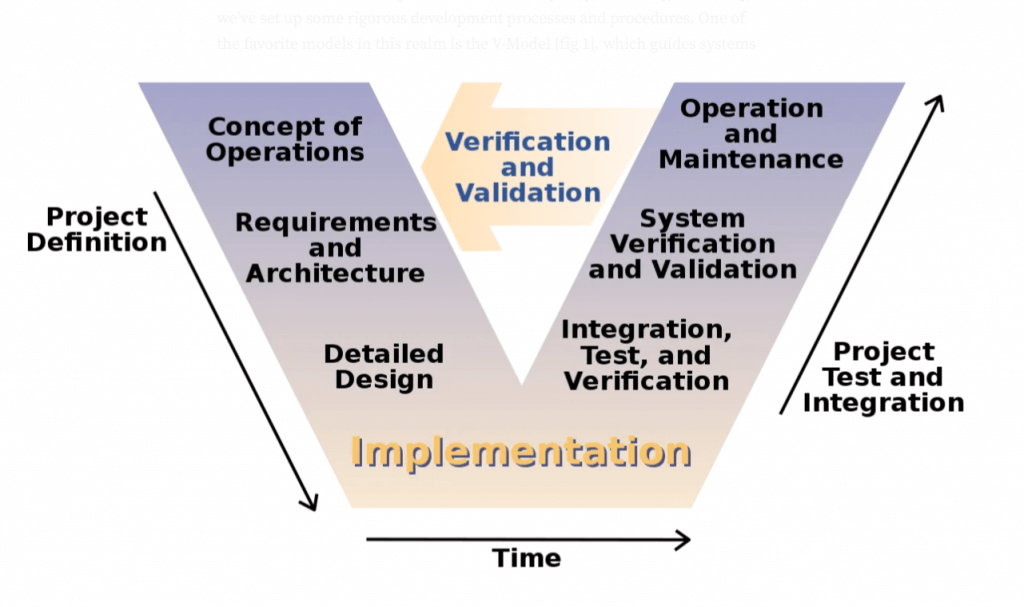

IBM ELM Global Configuration Management: IBM’s Engineering Lifecycle Management (ELM) Global Configuration Management provides a robust foundation for managing complex systems and software development in the automotive sector. It offers a centralized platform for managing configurations across the entire product development lifecycle. This means you can effectively manage variants, trace requirements, and ensure consistency across different product lines and versions.

Pure Variants: Pure Variants is a specialized variant management tool that helps you efficiently handle the complexity of automotive systems. It allows you to define and manage product variants, configurations, and constraints in a visual and intuitive way. With Pure Variants, you can create and maintain a clear overview of all possible product configurations, making it easier to reuse components and assess new technical solutions.

321Gang: 321Gang specializes in providing expert guidance and solutions for organizations in the automotive industry. They offer consultancy services and training to help your team effectively implement variant management practices using tools like IBM ELM Global Configuration Management and Pure Variants. Their expertise ensures that your organization can optimize its variant management processes and achieve the desired results.

By combining these three elements, you can establish a modern variant management solution that streamlines your automotive product development. You’ll have the tools to manage configurations efficiently, maintain consistency, and handle the complexities of variant-rich systems, ultimately improving the quality and speed of bringing your products to market.

To learn more about leveraging modern variant management, visit 321Gang. We work with enterprises to accelerate the engineering and development of large, engineered systems. 321Gang Consultants work with the industry-leading system builders of embedded software on best practices for requirements management, model-based systems engineering (MBSE), test management/verification and validation, and traceability for compliance and reporting. Visit our website or contact us to learn how we can improve your variant management capabilities.

By Tom Hollowell | 321Gang

321Gang | 14362 North FLW | Suite 1000 | Scottsdale, AZ 85260 | 877.820.0888 info@321gang.com