Beyond Asset Management: How Maximo Supports Strategic Engineering Operations

IBM Maximo is traditionally seen as a best-in-class enterprise asset management (EAM) solution. Organizations across industries rely on it to manage the lifecycle of physical assets, ensure regulatory compliance, and reduce operational costs. However, in highly engineered and regulated sectors such as aerospace, defense, energy, and transportation, Maximo’s value extends far beyond maintenance schedules and work orders.

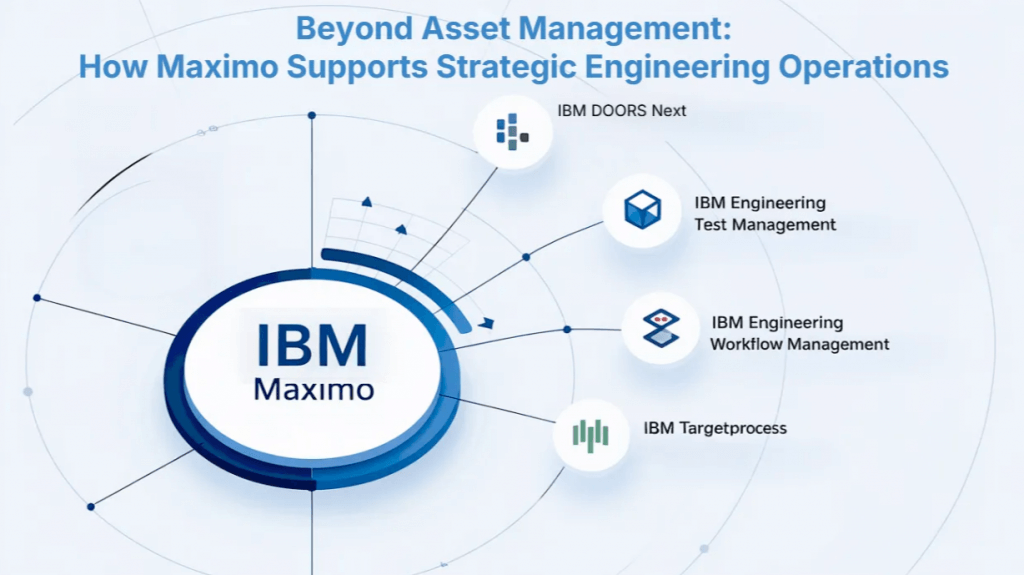

When integrated with other tools in the IBM Engineering Lifecycle Management (ELM) and DevOps ecosystem — such as IBM DOORS Next, Engineering Test Management (ETM), Engineering Workflow Management (EWM), and IBM Targetprocess — Maximo becomes a foundational piece of a broader systems and software engineering strategy.

This blog post explores both the opportunities and benefits of integrating IBM Maximo with other IBM solutions and how Maximo could be leveraged to support compliance, strategic decision-making, digital thread continuity, and enterprise-wide alignment.

Maximo as a Data Anchor in the Digital Thread

The concept of a digital thread — a seamless flow of data throughout the lifecycle of a product or system — is essential for modern engineering organizations. Maximo, as a repository for real-time operational data, provides critical inputs that can inform upstream engineering decisions.

When connected with IBM DOORS Next via OSLC (Open Services for Lifecycle Collaboration), Maximo allows operational teams to trace asset behaviors directly back to their original requirements. This traceability helps close the loop between design intent and in-field performance. For instance:

- Example Use Case: A turbine in an energy plant is exhibiting unexpected wear. The operational data captured in Maximo can be linked to its design requirements in DOORS Next, revealing that real-world operating conditions diverged from the original design assumptions. This insight informs future design iterations.

Similarly, Maximo can integrate with Engineering Test Management (ETM) to bring real-world performance data into the test environment. Engineers can:

- Adjust testing protocols based on actual failure modes captured in Maximo.

- Refine preventive maintenance plans using validated test data and field reports.

By feeding this data into ETM, testing becomes more predictive, efficient, and risk-aware.

Supporting Compliance Across Systems

Compliance is not optional in industries like aerospace, medical devices, and nuclear energy — it’s mission-critical. Maximo’s built-in capabilities for logging maintenance activities, managing calibration records, and enforcing workflows already support regulatory needs. But when integrated with ELM tools, Maximo becomes part of a holistic compliance solution.

- Change and Configuration Management: When a change request is initiated in Engineering Workflow Management (EWM), it can be linked to related assets in Maximo, allowing change traceability from design through operations.

- Audit Readiness: IBM ELM provides version control, baselining, and traceability. By integrating Maximo, audit trails now include operational states and asset histories.

- Deviation and Exception Handling: When deviations are logged in Maximo, they can trigger risk analyses and mitigation workflows within IBM Engineering Requirements Management or Risk Analysis tools.

With Maximo as a part of this integrated toolchain, compliance reporting becomes faster, more complete, and easier to defend during audits.

Integrating Maximo with IBM Targetprocess for Portfolio Insights

Enterprise leaders often lack visibility into how physical asset states impact portfolio performance. IBM Targetprocess, a lean portfolio management tool, can ingest Maximo data to:

- Show how downtime or asset availability impacts project timelines.

- Align maintenance plans with portfolio milestones.

- Visualize technical debt and backlog related to physical assets.

For example, Targetprocess dashboards can show how a delayed component repair (recorded in Maximo) is impacting the delivery schedule of a larger engineering initiative. This helps portfolio leaders make data-driven prioritization decisions.

Maximo’s work orders, asset states, and lifecycle events can be surfaced through Targetprocess using REST APIs or intermediate integration platforms. This allows asset-related data to sit side-by-side with Jira issues, user stories, test progress, and funding allocations — enabling strategic alignment across business and engineering.

OSLC: The Backbone of Integration

One of the key enablers of these integrations is OSLC, a set of specifications that allow lifecycle tools to share data and establish traceability across organizational silos. IBM Maximo is OSLC-compatible, which means it can:

- Create bidirectional links between assets and engineering artifacts.

- Embed previews and live data into other IBM tools (e.g., see a Maximo asset record inside DOORS Next or EWM).

- Maintain live, queryable relationships that update automatically when records change.

OSLC also provides permission controls and role-based access, ensuring that only authorized users can access sensitive asset or requirement data.

Improving Collaboration Between IT, OT, and Engineering

Many organizations struggle with the divide between Information Technology (IT), Operational Technology (OT), and Engineering. Maximo integrations help bridge that gap:

- IT Teams can use Maximo’s integration with ServiceNow or EWM to align asset issues with software incidents or change requests.

- OT Teams gain visibility into how physical system changes align with evolving software or firmware requirements.

- Engineering Teams benefit from asset telemetry that informs testing, requirements evolution, and defect resolution.

Bringing these domains together allows for unified incident response, better root cause analysis, and more efficient product lifecycle management.

The Fine Print — What is available today?

While these integrations are supported, they are not “out of the box” solutions. They require configuration and may involve some custom development:

- Maximo + DOORS Next: Integration via OSLC is technically supported, allowing for requirements traceability between the two systems. However, while the integration is feasible, specific real-world use cases may vary.

- Maximo + ETM: Integration with Engineering Test Management (ETM) via OSLC is supported, enabling operational data to inform test planning. Broader adoption of this integration is still developing, and implementations are more limited.

- Maximo + EWM: Integration with Engineering Workflow Management (EWM) is possible, supporting environments that require change management and incident tracking linked to assets. This integration has been implemented in certain environments, but use cases may differ.

- Maximo + Targetprocess: This integration is technically feasible using open REST APIs and integration platforms, and while it has been explored by some organizations, it requires customization.

Conclusion: A Smarter Way to Engineer and Operate

In industries where safety, compliance, and innovation are intertwined, siloed tools can’t keep up. IBM Maximo, when integrated with the ELM suite and planning tools like Targetprocess, enables a connected, compliant, and continuous engineering environment.

Maximo is no longer just a maintenance tool — it’s a strategic system of record and a catalyst for smarter engineering operations. With the right integrations in place, your teams can shift from reactive to predictive, from fragmented to aligned, and from compliant to continuously audit-ready.

Ready to connect the dots between your operations and engineering? Contact us to explore how these integrations can support your transformation goals.

321Gang | 14362 North FLW | Suite 1000 | Scottsdale, AZ 85260 | 877.820.0888 info@321gang.com